![]()

![]()

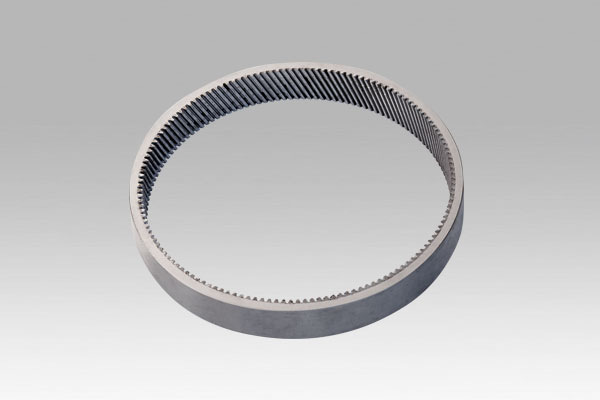

Hardening with very high dimensional accuracy

During die quenching, or press quenching as it is also known, the stresses induced in the material are immediately counteracted. The process requires not only special equipment, but also expert knowledge and skills.

The workpieces are mechanically constrained, which significantly reduces or even prevents dimensional distortion. The finished workpieces exhibit excellent concentricity (deviations of less than 30 μm depending on the component).

Thanks to our highly skilled teams and high-precision press-quenching equipment, we can guarantee optimum results every time.

Not all components can be die-quenched. We can test your workpieces to determine whether they are compatible with this process.

Any questions?

We’ll be happy to help.

You can get in touch by email or phone:

- 0049 7131 9092-0

Product examples

PROCESS

During press quenching, workpieces are held between restraining dies while they are heated and/or quenched. This minimises the distortion caused by the hardening process. Not all components can be die-quenched. We can test your workpieces to determine whether they are compatible with this process.